Sustainability does matter

Sensitive® Fabrics with RECO NYLON® offer considerable benefits in terms of appearance and above all environmental impact, ensuring the quality and aesthetic characteristics of the fabrics unchanged over time and the awareness of a responsible choice.

EUROJERSEY and NUREL’s product research focus on new consumer insights in terms of sustainability. They currently can offer a sustainable range of bio based polymers and recycled polyamide plastics and yarns. Such as RECO NYLON®, the nylon 6 yarn 100% made of pre-consumer waste. EUROJERSEY selected RECO NYLON® for its new Sensitive® Fabrics’ collection.

RECO NYLON® performance is similar to standard nylon 6 yarns adding sustainable advantages:

• Reducing dependence on non-renewable resources.

• Maintaining a clean landfill.

• Decreasing environmental impact.

FABRIC WITH GRS CERTIFICATION

GRS certifies that NUREL recycles the discarded nylon material divertied from the waste stream during the manufacturing process and reconverts it into RECO NYLON® yarn.

What is Global Recycled Standard?

• It is a mechanism created by Textile Exchange

• It aims to substantiate the recycled content

• It attests that all processes in the entire supply chain have undergone the proper steps to ensure the integrity of the final product

• It also addresses issues pertaining to environmental and social criteria

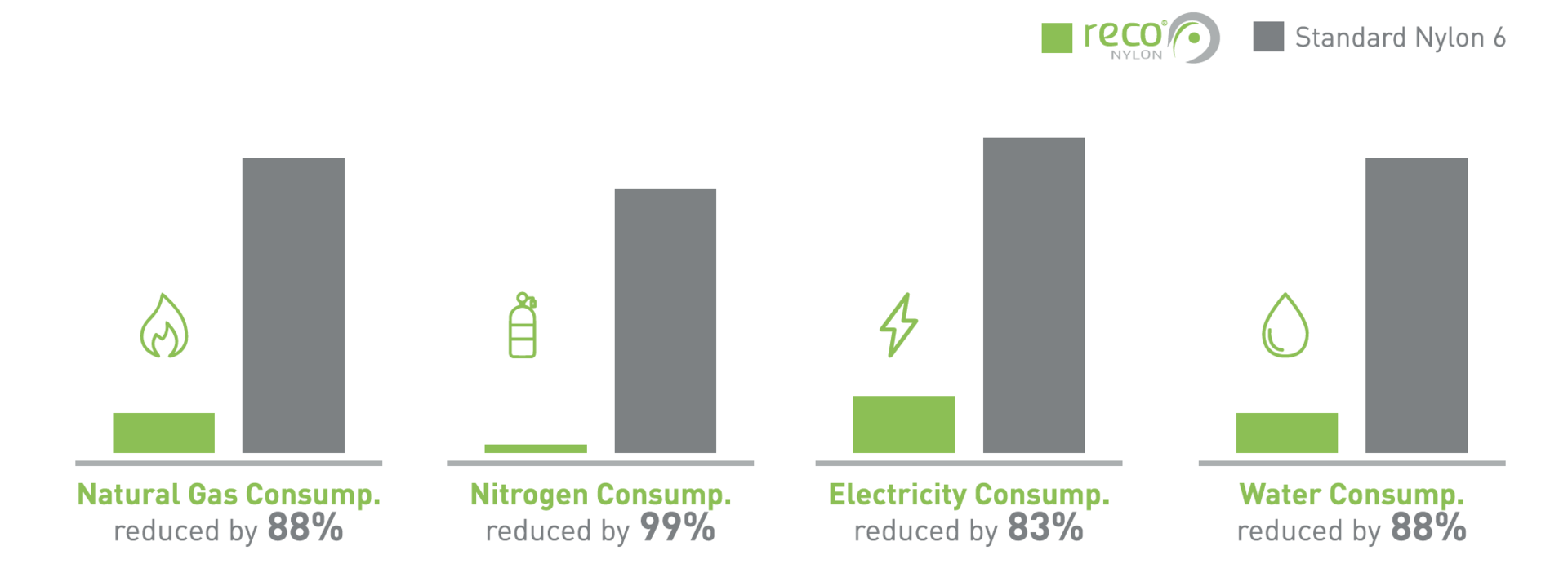

RECO NYLON® CONSIDERABLY REDUCES RESOURCES CONSUMPTION

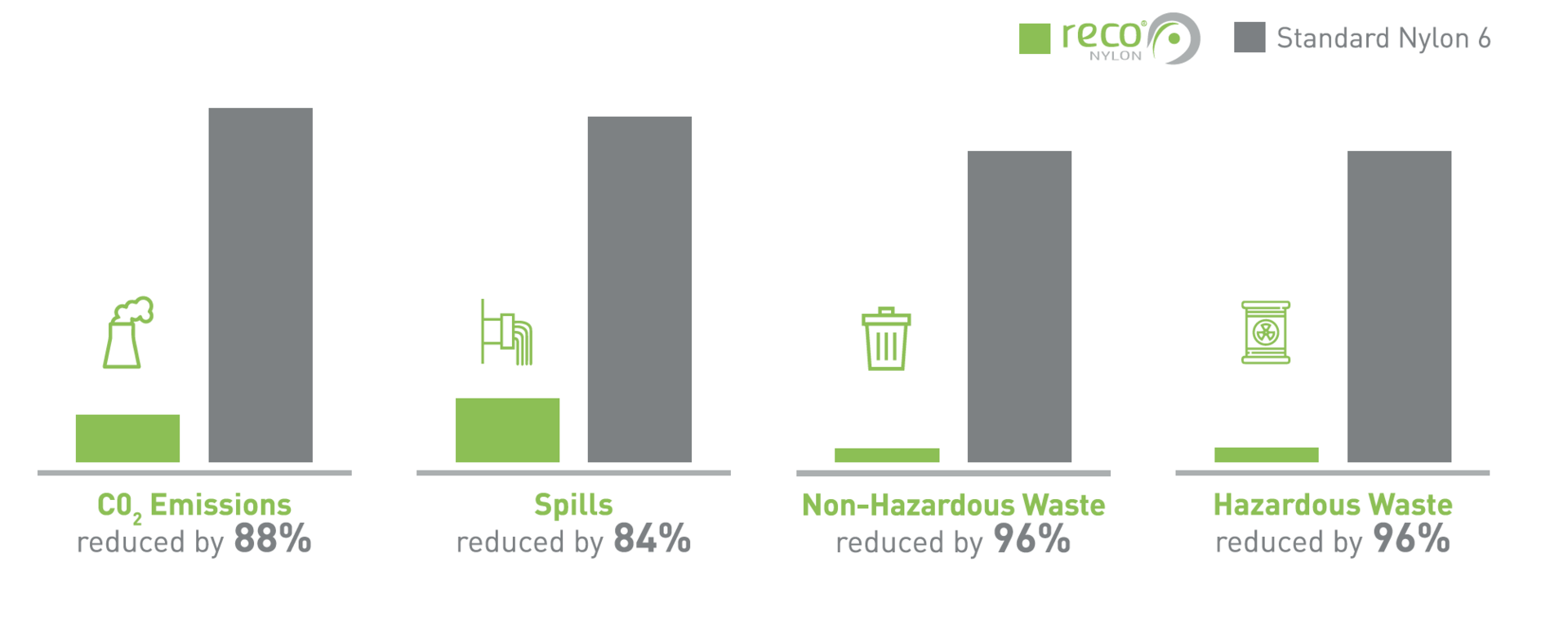

RECO NYLON® MINIMIZES CO2 EMISSIONS AND WASTE

ZERO KILOMETER,

ZERO WASTE

The production process of RECO NYLON® takes place entirely in NUREL premises in Zaragoza (Spain), thereby saving the environment CO2 emissions produced during the manufacture and transport of raw material.

THE PROCESS -

1. At a first stage NUREL select and adequate the reclaimed material from all the waste generated in our textile facilities.

2. Reclaimed material is remalted at NUREL recycling units in order to obtain a recycled PA6 polymer.

3. Recovered polyamide polymer is extruded and made back into fibers at NUREL spinning plant.

SENSITIVE® FABRICS WITH RECO NYLON®

Sensitive® Fabrics with RECO NYLON® offer considerable benefits in terms of appearance and above all environmental impact, ensuring the quality and aesthetic characteristics of the fabrics unchanged over time and the awareness of a responsible choice. The production of RECO NYLON® generates almost 9 times less CO2 emissions than standard nylon 6. Therefore, a production of 1 ton of RECO NYLON® reduces the emissions of an equivalent to:

1. CO2 produced by a car driving 8.191 km

2. CO2 produced by 265.451 phones being charged

3. CO2 absorbed by 101.000m2 of forest in a year